by John C. Harris

July 2015

![]()

"Wale" is an Old English word that means "ridge" or "rib." It seems to have taken on its nautical inflection, "a ridge of planking along the rail of a ship," upwards of a thousand years ago. It became a "gunwale" as soon as there were guns to mount there, round about the 14th century. Down the ages the suffix "-wale" came to be attached to various bits of wood around the top edge of a boat. There are outwales (also known as "rubrails") and inwales. Scholarly prelude disposed, we'll tuck into the installation of inwales in smallcraft.

"Wale" is an Old English word that means "ridge" or "rib." It seems to have taken on its nautical inflection, "a ridge of planking along the rail of a ship," upwards of a thousand years ago. It became a "gunwale" as soon as there were guns to mount there, round about the 14th century. Down the ages the suffix "-wale" came to be attached to various bits of wood around the top edge of a boat. There are outwales (also known as "rubrails") and inwales. Scholarly prelude disposed, we'll tuck into the installation of inwales in smallcraft.

As long as CLC has been putting out small rowing and sailing boats, folks have been fitting them with inwales. Some of these designs always had them (the Sassafras canoes, the Jimmy Skiff, the Peeler Skiff), but on others the inwales were left off for simplicity, ease of construction, and economy.

Nothing does more to accent the elegant sweep of a traditional boat's sheerline than a nicely proportioned rail, and many are inspired to dress up their boats with so-called "spacered" or "scuppered" inwales. These are longitudinal rails glued to the inside upper edge of a boat, with a zillion little wooden blocks elevating the rail off the plywood. The spacered inwales are a new invention, mostly unknown until maybe 30 years ago. What the blocks are doing is imitating the tops of the steam-bent frames in traditionally-built boats. (Here's a perfect example.)

So spacered inwales are an affectation to some extent, but they are genuinely practical in two ways: they create handy lashing points the whole length of the boat, and if you want to tip the boat up on the beach to drain the water out, the gaps (or scuppers) created by the spacers allow all of the water to run out.

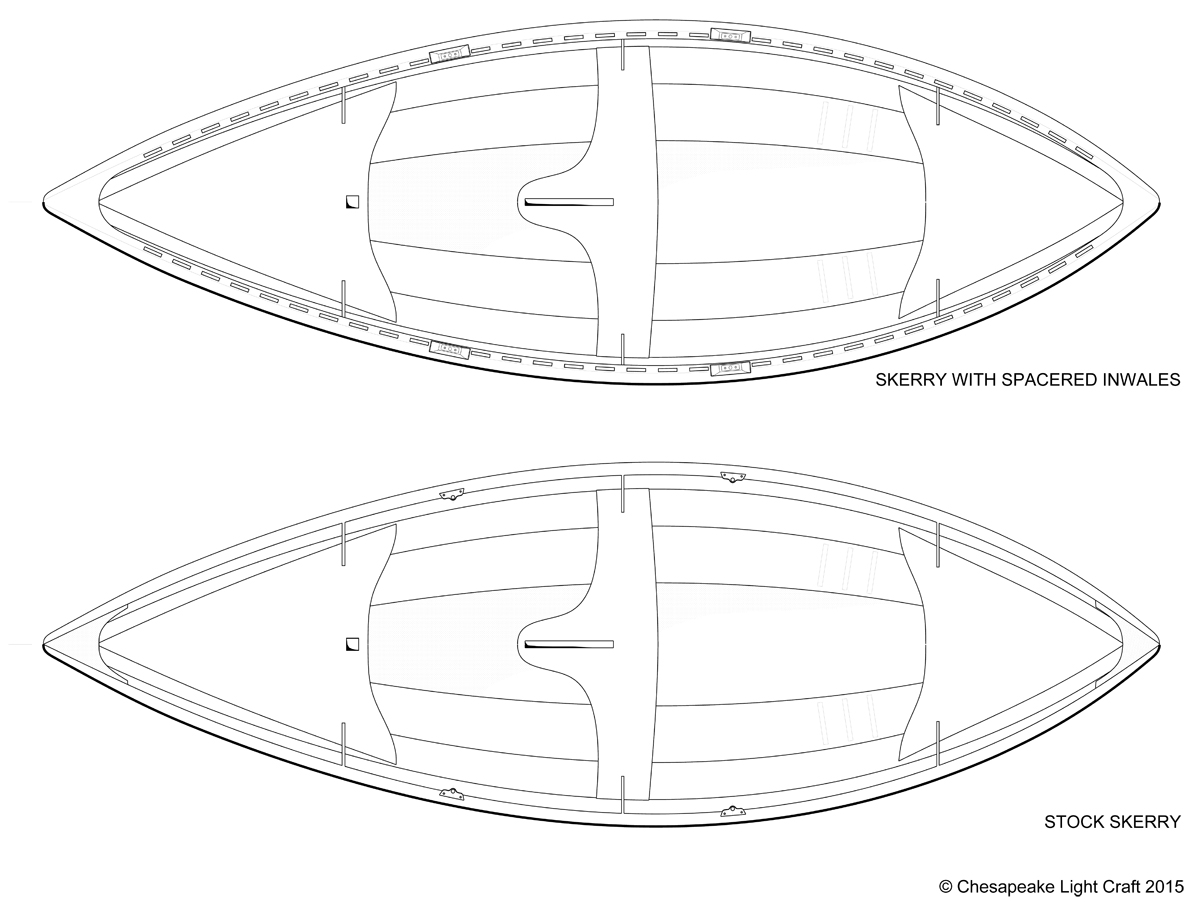

Here we have two Skerries in CLC's demo fleet, absolutely identical in every respect, except the one on the left has spacered inwales, is brand new, and is fully kitted out with the posh nonskid flooring. The one on the right is ten years old, doesn't have inwales, and has a somewhat tired finish.

Okay, that was easy. The Skerry on the left is just plain...prettier. That spacered inwale is a sophisticated, craftsmanlike way to kick it up a notch. It's shipshape and looks right.

(Click on images to enlarge.)

So why don't we ship spacered inwales with every boat? Well, I'll give you 77 reasons. 77 is how many photos and drawings it took to illustrate how to do a neat job of installing spacered inwales, and why this page took so long to load. Like many things in boatbuilding, the concept is straightforward, but the execution is fussy. A great many builders, admiring the spacered inwales on someone else's Northeaster Dory or Skerry, resolved to add inwales and discovered that the things can be a right cross-grained bastard.

Let's review the pros and cons.

On the plus side, spacered inwales look brilliant. They provide real utility as lashing points for mooring lines, fenders, and gear. And they will add a bit more stiffness.

The downsides are: 1) The joinery is not trivial. There's some real woodwork here. 2) They are quite time-consuming to install. 3) All sorts of modifications will be necessary. Breasthooks, frames, quarter knees, and other structures will require alteration. (A lug-rigged Northeaster Dory, for example, is going to require some real head-scratching to combine the mast thwart with an inwale.) 4) The oarlock sockets that came with your kit are going to have to be ditched and top-mount sockets procured. And 5) the top-mount oarlock sockets will require special reinforcing pads.

Assuming you are undeterred, let us seize the bull by the horns and get right to the complex bits.

This is the Skerry's stock breasthook, a structural gusset at the bow and stern. It's made of 3/4-inch plywood, neatly beveled to fit between the sides of the boat. It takes a couple of minutes to install and does yeoman work stiffening the hull and functioning as a grab-handle when carrying the boat.

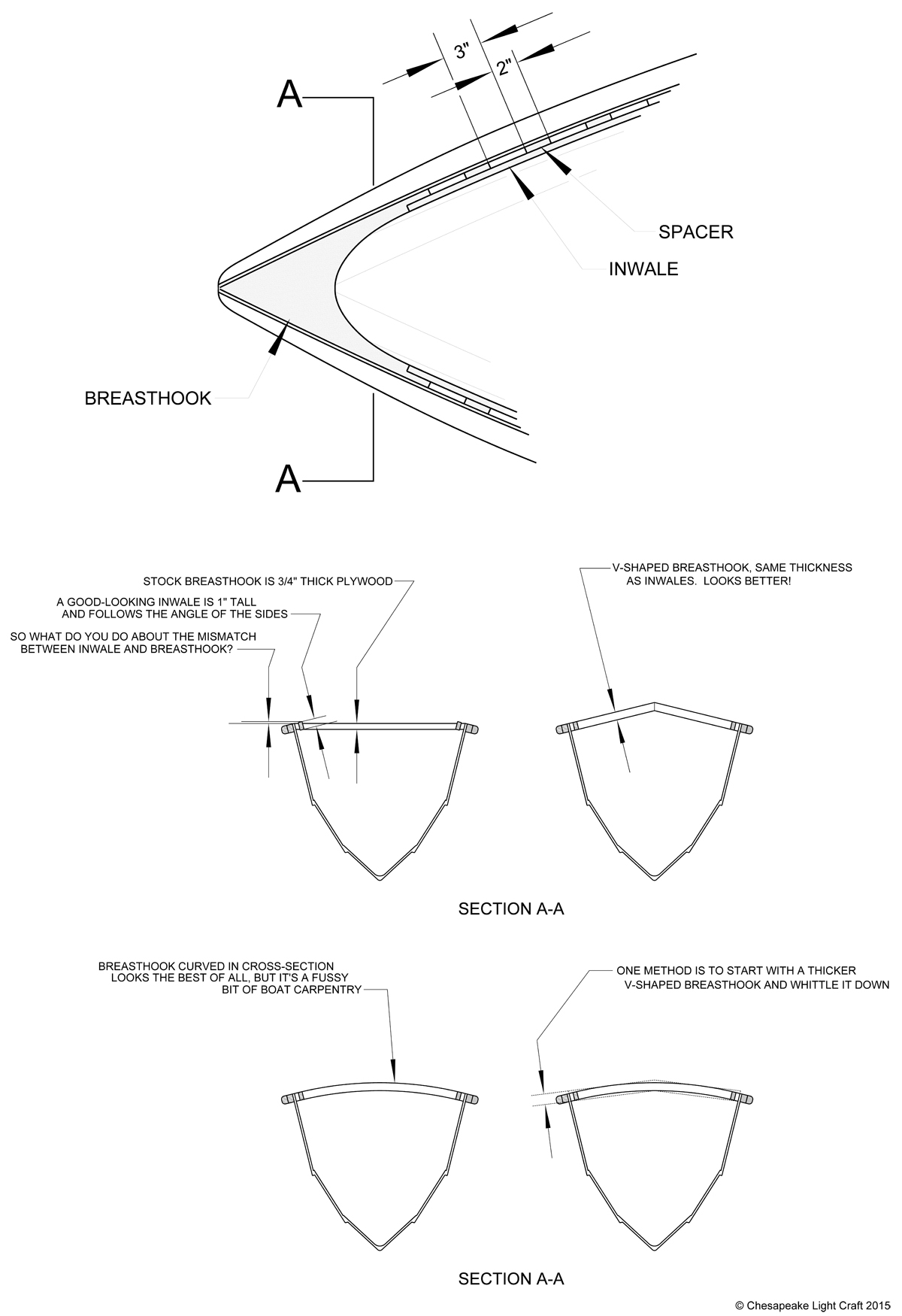

It's also the main reason spacered inwales aren't a plug-and-play thing in these boats. To understand why, we need a diagram (click to embiggen):

Study the first cross section, which shows the stock, straight-across plywood breasthook. The inwales are glued to the inside of the top strake, and thus angled to match the boat's flared sides. The inwales must terminate neatly at the breasthook, but they land on the straight-across breasthook at an awkward angle. Some builders shrug and just sort of make it work, but this will look makeshift.

There are two solutions. The first, shown in the second cross-section above, is to make the breasthook of the same thickness material as the inwales. The breasthook is now in right and left halves, which meet on the centerline in a V-shape.

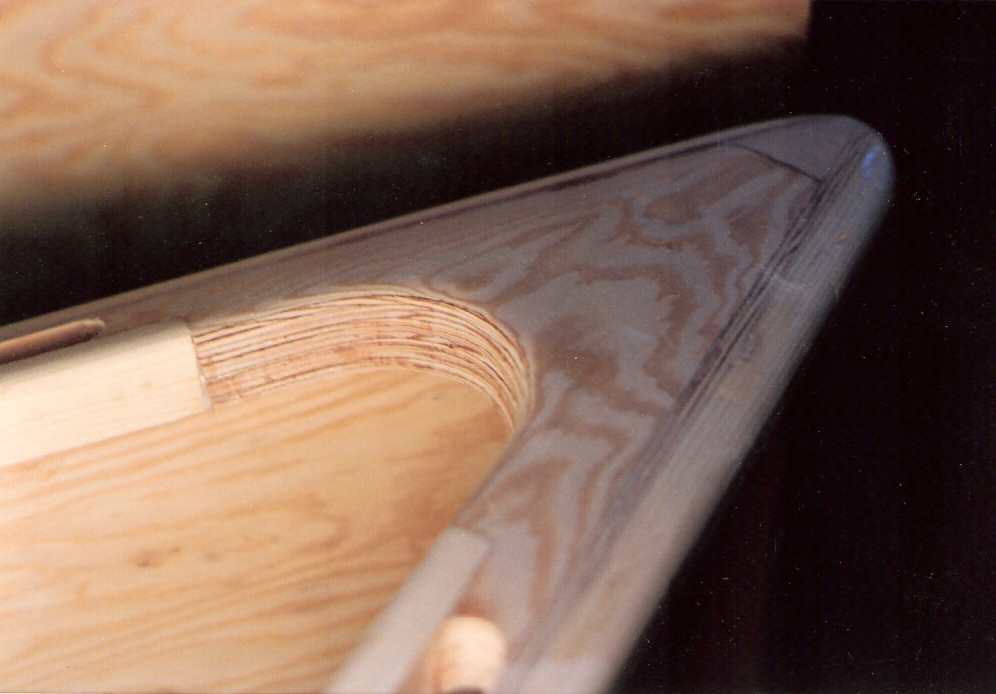

A V-shaped breasthook on a Skerry. This is the easiest way around the challenge of creating a neat terminus for the inwales at the breasthook. It's the approach I'll illustrate in the step-by-step guide, below.

A fancier way to manage this challenge is for the breasthook to arch from one side to the other like a violin top, as in the bottom two cross-sections in the drawing.

You can laminate the breasthook from layers of plywood or veneer into an athwartships arc. That's how my college buddy Jeff and I handled the breasthooks on this little double-ender. Sheesh, over twenty years ago now.

The Peeler Skiff (which includes spacered inwales as standard equipment in the kit) has a breasthook that arcs from side to side in a gentle curve, as you can see in this head-on view.

It isn't laminated, however. We start with a V-sectioned breasthook, then carve the athwartships radius into it. This requires chunks of wood considerably thicker than the inwales, so you have enough material to whittle the thing down to the correct shape. It's straightforward wood butchery for the patient, easy-going boatbuilder types.

The Skerry is a double-ender, so we have a breasthook at either end to deal with. Boats with transom sterns, such as this Peeler Skiff, require "quarter-knees" for the aft terminus of the spacered inwale.

The finished quarter knee on a Peeler, very neatly proportioned.

Here are the quarter knees on a Southwester Dory, fitted with the optional spacered inwales.

The Southwester Dory's quarter knees, varnished and ready for showtime.

Back to the Skerry's spacered inwales. We begin by creating a pattern on a piece of scrap for the breasthooks at the bow and stern. We'll want a pleasing sine curve joining left and right halves, so that the beholder's eye follows the sweep of the inwales from end to end, with no awkward kink at the breasthook. Note that the notches where the inwales will land are shown on the pattern.

A session at the bandsaw with a chunk of mahogany and some careful cutting and fitting yields left and right breasthook halves that join down the centerline.

A snug, clean fit at the Skerry's bow.

Spring clamps hold the breasthook while you take note of any necessary adjustments. (Note that the outwales have already been installed. It would be smart to have the Skerry's stock plywood breasthooks wedged in place temporarily during hull assembly to ensure that your bow and stern are shaped correctly.)

Here's the stern breasthook on the Skerry, ready for gluing.

Gluing the breasthooks is very easy! Place a strip of masking tape on the top surface of the breasthook...

...Then flip the taped-together breasthooks over on the workbench. The beveled centerline joint opens up when the breasthooks are laid out flat.

Work some thickened epoxy into the centerline joint...

...Squish the breasthook together...

...Clean up the squeeze-out....

...Then set the breasthooks down, right-side-up, on supporting blocks. The masking tape holds the joint tight, while the weight of the breasthook ensures good contact while the epoxy cures.

When the epoxy has cured, peel the tape, and you're ready to install the breasthook assemblies in the boat. Brush thickened epoxy onto the mating surfaces...

...And a few spring clamps should be all that's required for a neat fit. Let the epoxy cure.

Now we'll make the rest of the boat ready for the inwales. Like most of our smallcraft, the Skerry's structural bulkheads extend right up to the sheer line of the boat, very much in the way of the inwales. We used a router with an end-mill bit to zip off the tops of the three bulkheads where the inwales will rest.

It takes steady hands and a courageous heart to freehand this with a router, but here's the result: the top of the frame has been neatly milled out to receive the 7/8th-inch tall inwales.

If you don't have a router, or you fear the mess it can create, one of these little pullsaws is just as quick and effective at nipping the bulkhead tops.

Test the fit of a sample section of inwale and spacer in the bulkhead notches.

A sharp wood rasp is handy for touching up the notches as needed.

Now it's time deal with the inwale spacer blocks. What's the proper length and spacing? There is no correct answer. It's whatever looks good. But there are practical considerations. We wanted spacers to cover each of the Skerry's bulkhead tops, just for aesthetic reasons. To do so and maintain an even spacing of the blocks from bow to stern required much experimentation. We simply made a couple spacer blocks of different lengths and tried them out on the boat until we found a combination of block length and spacing that worked.

Trying out the blocks. We used spring clamps for a dry run. Ultimately we settled on a block two inches long, and a spacing of three inches. It'll be different on every design and you need to be willing to experiment until you're happy with the look of it.

With that settled, we milled up a heap of 1/2" x 7/8" x 2" blocks, ready to glue in the boat.

We did a full test-fit with spring clamps before we mixed epoxy.

Whoops. The two-inch block/three-inch spacing wasn't perfect. We had to cheat the block spacing at the ends. This is fine. But if I hadn't pointed it out to you, you'd never have noticed it in the finished boat.

Glove up, and brush paste-consistency epoxy on each block...

...and clamp them in place. Note the three-inch block, which is used to establish the spacing between each two-inch block glued to the hull.

Note how the block lands atop the bulkhead as intended.

It's worth pausing here to note that there are many different ways to handle this step. Some builders actually mill the spaces out of their inwales. In other words, inwale and spacer blocks are the SAME piece of wood. This is as tricky as it sounds, requiring much forethought and a clever router jig. This approach leaves no room for error at any stage and is best left to confident cabinetmaker types.

Another approach is to glue the spacer blocks to the INWALE over on the bench. The cured assembly is cleaned up, then brought over and bent into the boat. Again, this requires a lot of fiddly fitting and there are a couple of steps in that particular sequence that can result in expensive kindling for the wood stove.

Gluing the blocks to the hull first is a reasonable and forgiving compromise between ease of assembly, expenditure of time, and a neat finish.

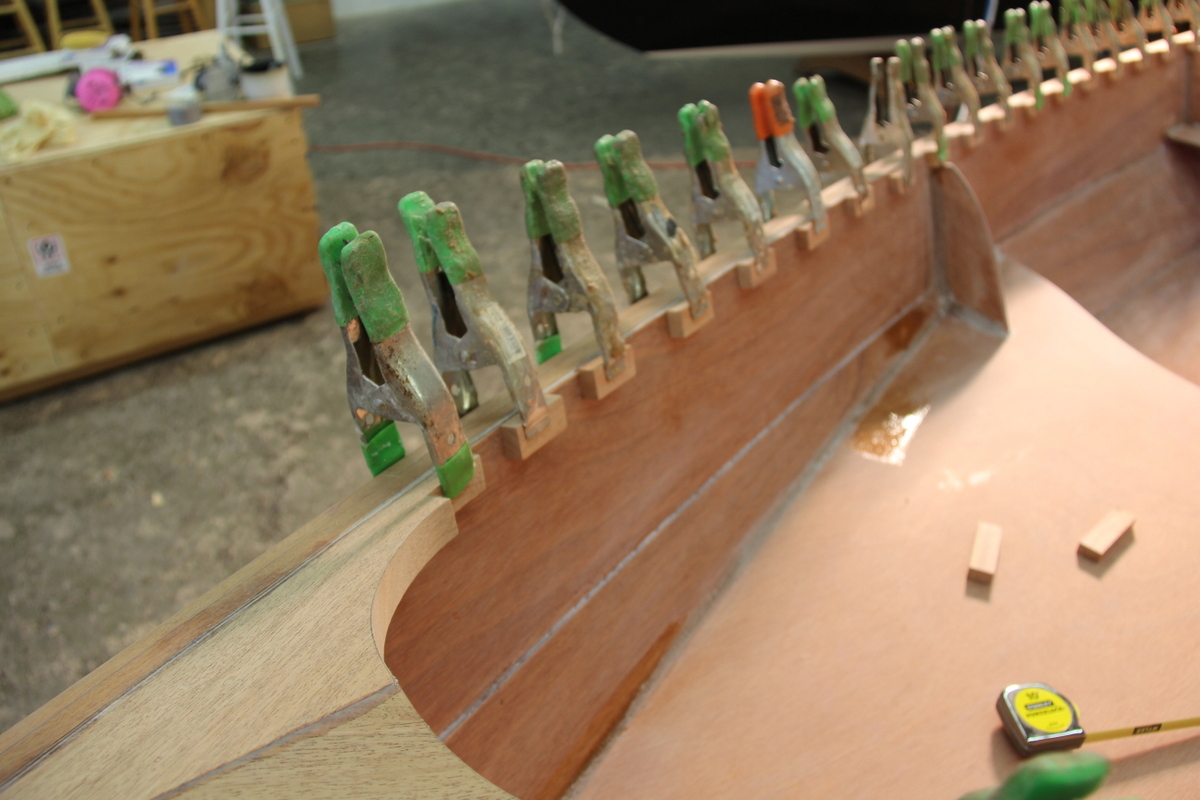

Muster all the spring clamps in the neighborhood for the spacer-block gluing procedure. Something like 30 blocks per side are required for a Skerry.

If you aren't slavish in cleaning up the squeezed-out epoxy, you will have a godawful mess once it cures and you might as well round up some accelerant and a book of matches.

We scraped off the epoxy with a plastic spreader, then went round again with a rag and denatured alcohol to clean up every last vestige of excess epoxy.

Once the spacer blocks have cured, their ends and undersides need to be sealed with a couple of coats of epoxy. Trying to seal these bits AFTER the inwales are glued on is a goat rodeo.

Patient, careful, and persistent sanding prepares the blocks for easy varnish work a few steps down the road. Note that the inboard faces of the blocks, to which the inwales will be glued, were NOT coated in epoxy.

Off to the side, you've assembled and milled your inwales, in the case of the Skerry 1/2" x 7/8" in section. We've already run the inboard faces through the router table for a neat round-over. And if ever there there was a case for pre-finishing components on the bench, here it is. We applied several coats of epoxy to all four faces of the inwales.

In order to coat all four sides of each rail in one operation, the rails rest on triangular blocks of wood protected with packing tape.

It's hard to sand skinny sticks like this without cutting through your epoxy coating. It's best done by hand, as seen here. We took the rails all of the way to 220-grit.

There are plenty of opportunities during this inwale business to hose things up, and the next step accounts for 8 out of 10 catastrophes. This is where we fit the inwales for length. Those outwales were smooth sailing: they were glued on a bit long, and we'll trim them off at our leisure. The inwales? You gotta nail the length. It is awfully easy to cut them too short. So take this slow and remember that it's easier to take wood off than it is to put it back on.

Begin by seating the inwale firmly in its notch in the stern breasthook (or quarter knee in transom-sterned boats). Add a number of clamps along the length of the boat. You want the inwale in contact with the spacer blocks EVERYWHERE. If the inwale is allowed to take a shortcut somewhere along the curve, you're going to cut it too short and end up with an ugly gap at the terminus in the breasthook. Very uncool.

Here's the inwale at the bow of the Skerry, a couple inches too long. Now, to cut it exactly to length...

A steel straightedge is used to mark the rail for cutting.

Slip a bit of scrap under the inwale and use a sharp, fine-toothed pull-saw to cut off the excess length.

Still a bit too long? Patiently work the inwale down with a rasp and sanding block.

You've nailed it if you need a light tap from a hammer to slot the inwale in place.

A perfect fit in the breasthook!

Out comes the glue, dabbed on the spacer blocks.

Your author, looking dazed and sleep-deprived, puts the camera down to help lever the inwale into place.

Minimizing the glue mess is essential here. Start with a couple of spring clamps to settle the inwale in place. Note C-clamps staged and ready.

Watch the alignment! Don't want to glue the inwale in too high or too low in the boat.

We'll want one clamp per spacer block. Note the proper alignment and a bit of squeeze-out. Not too much squeeze-out, though! Epoxy likes contact between surfaces, not crushing pressure. Our 3-inch spring clamps weren't quite wide enough to span the outwales and inwales, so we had to gather up every C-clamp and bar clamp we could find, and even then could do only one side at a time.

Once again, the emphasis is on infinite care in cleaning up the excess epoxy. If you let squeezed-out epoxy cure in the spaces between hull and rail, chipping it out is going to require dentistry equipment, and will be about as much fun.

Scraping excess epoxy off the undersides of the rails.

Finally, a disposable foam brush is used to clean up every space.

The port side has cured, and we've installed the starboard inwale. If you look close, you can see a lead ingot on the port side of the center thwart. It's there to keep the weight of the clamps from capsizing the boat to starboard.

With the epoxy cured, we can do our final shaping and cleanup. Using the nearest convenient radius (a roll of tape), the outwales are shaped at the bow and stern.

A 5-inch random orbital sander with 120-grit is used to flatten the tops of the rails. Yes, you'll sand off some of the epoxy you applied to the inwales in earlier steps, but not on the impossible-to-reach inboard and underside faces.

Smoothing the breasthook at the bow.

The round-over we gave the inwales was continued around the inside perimeter of the breasthook.

Patient sanding continues until the rails gleam.

Out comes the epoxy for a couple more coats on the tops of the inwales and outwales where we sanded through.

Neatness cannot be over-emphasized at this stage. Andrew made himself this little masking device from a scrap of wood to protect the hull from excess epoxy. Note the masking tape, which also keeps excess epoxy off the hull interior. The interior was finish-sanded to 220-grit, ready for varnish, before the rails were installed.

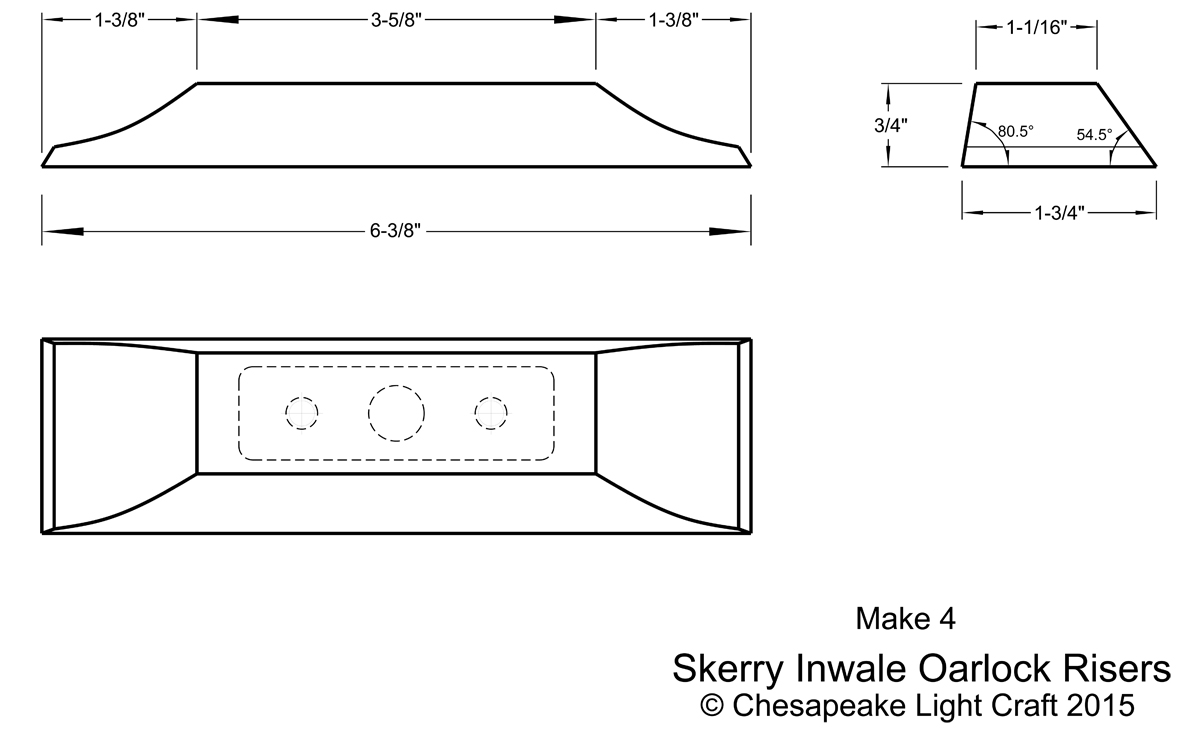

Time to install our oarlock mounting blocks. The inwale-and-outwale combination is too wide for the side-mount oarlock sockets to work. We'll need top-mount oarlocks, and we'll need to give them some elevation so that the oar will clear the rails on each stroke. These mounting blocks are what worked for our Skerry:

The top-mount oarlock sockets not only need some elevation to work, they also need the mounting blocks to reinforce the inwales. The reason is that you'll need to drill a heaping great hole right through your inwale, through which the oarlock's pin will pass when dropped into the socket. The mounting locks are glued on BEFORE you drill this hole in the inwales, and thus you avoid the horror of the hole throwing a nasty kink into the inwale's curve.

We bandsawed the mounting blocks from mahogany...

...Drilled the hole for the socket...

...And tested the fit on the boat. The carefully-designed angles in the sides of the mounting blocks position the oarlock socket so that the hole for the oarlock pin passes inboard of the plywood hull side.

The mounting blocks are epoxied in place. After the epoxy cures, we'll finish drilling the hole the rest of the way.

Drilling the hole through the inwales for the top-mount oarlock sockets. This is a Southwester Dory. Note the scrap of wood clamped tightly to the underside of the rails to prevent tear-out as the drill bit emerges. If you've oriented the oarlock risers correctly, you'll miss the plywood hull! Don't forget to seal the holes with a dab of epoxy.

And finally, it's time for varnish. Applying varnish to spacered inwales is finicky business. Note that Andrew is varnishing the hull interior FIRST. Then he'll make the rounds and varnish the rails SECOND. That way he can lean over the dry rails to reach the interior for varnish work.

And that's it. Here's a Southwester Dory with spacered inwales. It's a lot of work, but the patient builder is rewarded with detailing worthy of a yacht.

Pre-cut inwale kits, including breasthooks and/or quarter knees, are available for most of our smallcraft for around $350.

return to section:

return to section: