Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

I took my dory for the first sail with decent wind this week and once the speed picks up a bit, the rudder vibrates. This is amplified by the tiller arm. Any ideas what to check? Otherwise, a great day on SF Bay!

Barry

20 replies:

RE: NE Dory rudder vibration

Barry, I know the leading edge of the dory rudder is way up under the transom so you may not be able to see it, but by chance could you tell if the rudder was cavitating, meaning sucking air or making bubbles?. You would see bubbles on the surface of the water around the rudder. You may even feel less rudder effectiveness when it's cavitating. Do you think that it may be cavitating? And just to confirm is your rudder mounted so that the bottom of your rudder is slightly below the bottom of the skeg like it shows in the CLC build manual?

Curt

RE: NE Dory rudder vibration

I had a fiberglass rudder on a snipe I race vibrate badly. Turned out to be a bubble in the glass ~1.5" diameter and maybe 1/8" proud of the surface on one side of the rudder. Ginding her back to fair solved the problem.

good luck,

Joel

RE: NE Dory rudder vibration

Thanks for the feedback. I will mount the rudder to check positioning. There is no play in the pintle/gudgeon setup. When I built the rudder, I just rounded over the edges since I think the manual said to. Should I taper the trailing edge? I'll also check for any lack of flatness. There did not seem to be any vibration in the dagger board.

Barry

RE: NE Dory rudder vibration

Surface wierdness is one possibility- good rudders vibrate when there is kelp or grass wrapped on them. Such a surface defect is pretty unlikely on a new build, so my bet is the trailing edge.

You wrote that the edges were rounded. If the trailing edge is rounded, it will almost definitely shed vortices in an oscillating pattern.

(See karman vortex street: http://en.m.wikipedia.org/wiki/Kármán_vortex_street ).

The larger the radius, the slower the oscillation. Race boats with small trailing edges often hum; your bigger radius is a lower hertz process that you can feel rather than hear. In all cases, the answer is to make the trailing edge deliberately asymmetric by sanding a bevel or chamfer. This causes all the vortices to shed on the same side, rather than oscillate. Theoretically this makes one side of the foil slightly more efficient, but you really won't notice it.

(This definitely isn't "cavitation", and although ventilation -air sucked down the low pressure side- is possible it'll manifest itself as loss of rudder authority at speed and at high rudder angles and although you may hear gurgling you won't hear a hum and probably won't feel vibration- just a mushy ineffective steering sensation. Similarly, "stall" requires significant rudder angle -unless the foil is badly misshapen- so unless you sail with the sails badly trimmed and lots of constant rudder angle, stall isn't possible.)

RE: NE Dory rudder vibration

Hey nemochad.. Could I get your thoughts on this?....I will be working on the wet edges of the rudder tonight and finishing tomorrow...I'm epoxying 3/8" rope into a shallow concave groove on the leading and bottom edges and filling with thickened epoxy, so those edges will have a nice smooth bullet shape, but I wont be doing rope on the trailing edge...I was planning on about a 3" wide taper down to about a half inch thickness then rounded. Same thing on the daggerboard but the trailing edge would be a little narrower and the taper maybe more like 4"...your thoughts/suggestions?

Thanks

Curt

RE: NE Dory rudder vibration

Karman streets are cause by blunt leading edges, not trailing edges, and happen on objects with cylindrical cross sections, not plates or airfoils. In fact, one of the ways to fix Karman streets is to attach a plate to the downstream side of the troublesome cylinder.

Untapered trailing edges cause stalling when the flow separates at the premature ending of the foil. Symmetrically tapering the foil lets the attached flow continue and smoothly leave the foil.

Laszlo

RE: NE Dory rudder vibration

I think the trailing edge plate (and every sailboat racer's experience) proves that the trailing edge bluntness causes the vortices. No foil has zero-thickness trailing edge, so at a "real" level, all foils are similar to cylinders at their trailing edge. The answer from every boat designer is to deliberately introduce asymmetry to the trailing edge by using different radii, or bevelling the edge at a 30 or so degree angle.

Here's one graphic I could find to show what is ideal:

http://www.tboat.com/Editorials/Edit-designer/sport-fast.html

-adjust that to your foil size, and your chosen building methods and materials. For a glassed wood foil, I'd add a slug of resin to the trailing edge before glassing, then radius one side more than the other. If your target trailing edge is 1/2", then aggressively radius one side to 3/8", and gently ease the other edge to 1/16 - 1/8" radius.

Note that these oscillations occur in lots of foils, and the foils need to be fairly symmetrical for it to occur. Usually the sound/vibration goes away when the foil is loaded (tiller is turned). Many rudders are built symmetricly, and then the aft edge gets chamfered to fix the problem later if it shows up- if the builder got the foil and trailing edge symmetrical enough, and the boat sees speeds that trigger the problem. It's almost always a no-big-deal fix, involving a few minutes with a coarse sanding block. So make sure you've got room to sand the trailing edge, by adding that slug of edge epoxy. It's good for wear, and damage tolerance, too.

RE: NE Dory rudder vibration

Close up of foil with beveled trailing edge, still shedding vortices:

http://m.youtube.com/watch?v=Jsq1rwUBcUw

RE: NE Dory rudder vibration

Nemochad, I watched the Karman video and at the end it confirmed that the asymmetric forces partially cancelled, reducing vibration. Are you then in agreement that this configuration should be recommended for the Dory rudder? I'm at the stage of the first epoxy coat, so this recommendation could be followed immediately.

thanks for this documentation!

Jim

RE: NE Dory rudder vibration

Check your rudder blade for fairness before unnecessarily messing up the trailing edge.Laszlo

RE: NE Dory rudder vibration

The Northeaster Dory's 19th-century "barn door" rudder is shallow and broad and operates mostly in disturbed water. As a simplification for the builders, no trailing edge taper was indicated in the instructions.

The blunt trailing edge is the cause of vibration and will appear only at comparatively high speeds. In scores of hours of sailing our demo model, I've noticed the vibration, but it was neither distracting nor a detraction to performance.

I think if I was sailing in heavy air often, I might consider some taper on the rudder's trailing edge, but I feel no inclination to make that modification to my boat.

The Northeaster Dory's daggerboard, deep and narrow and operating in clean water, is given the full bullet-nosed, aggressively-tapered trailing edge treatment.

Other CLC boats with deeper rudders---the Passagemaker, Skerry, Eastport Pram, Jimmy Skiff, and various multihulls---have completely shaped rudder blades.

RE: NE Dory rudder vibration

John,

Thanks for jumping in with a comprehensive summary. That pretty much addresses all the issues in this thread I'd say.

Curt

RE: NE Dory rudder vibration

Thanks for all the feedback.

John, since I am having the vibration, I will taper the trailing edge of the rudder. How much taper would you recommend? I'm also looking forward to visiting the dory build at Spaulding Boat Works in June.

Barry

RE: NE Dory rudder vibration

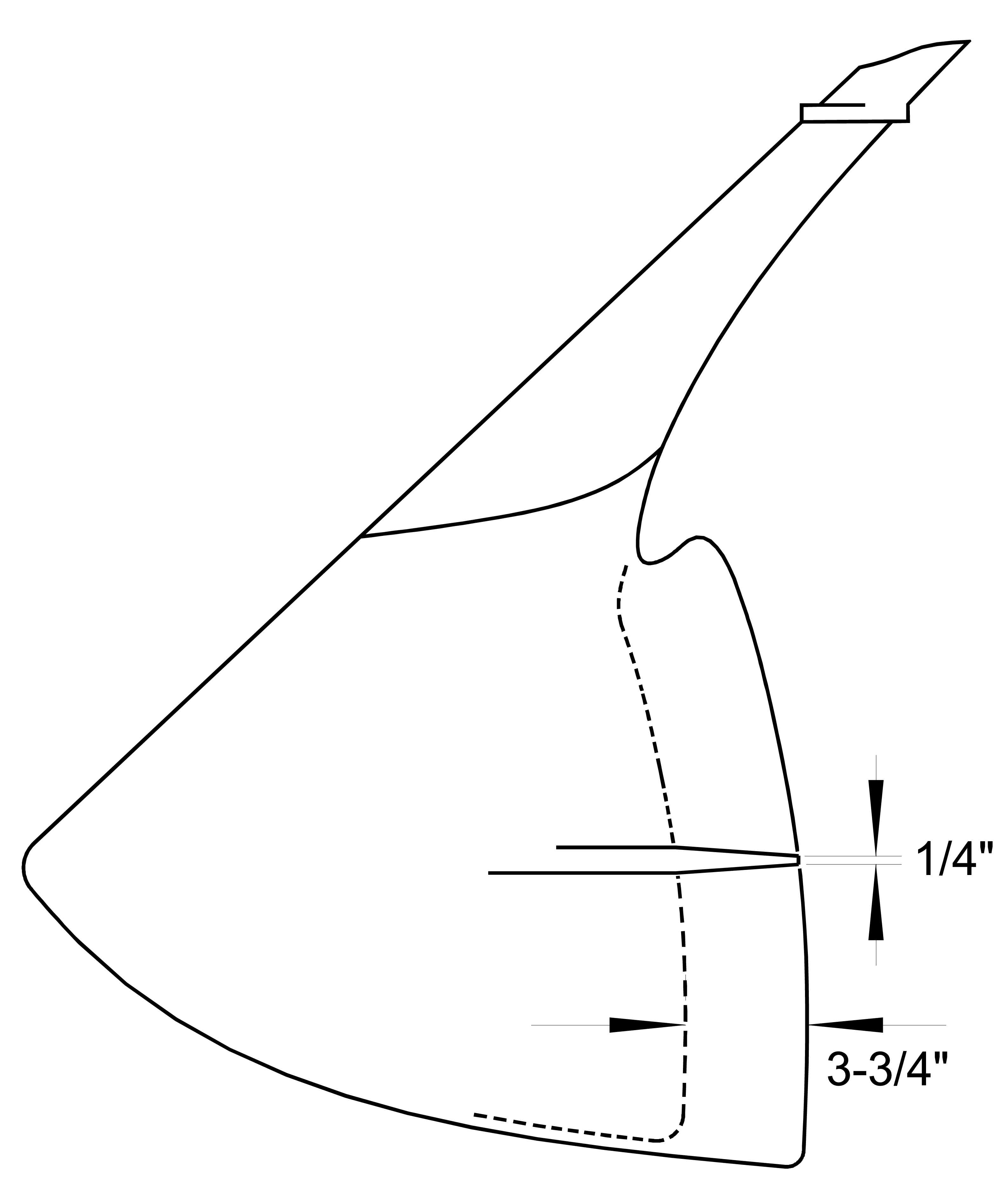

A taper of around four inches, give or take, with a trailing edge thickness of 1/4", will put an end to the turbulence. The trailing edge should have sharp corners, preferably.

RE: NE Dory rudder vibration

>>>does tapering the rudder also give a better feel, and carve turns more smoothly even at medium speeds?>>

No, the difference won't be noticeable. Speaking as a competitive dinghy racer, famously fussy about foils, I won't be recommending any change to the shaping of the stock Northeaster Dory rudder.

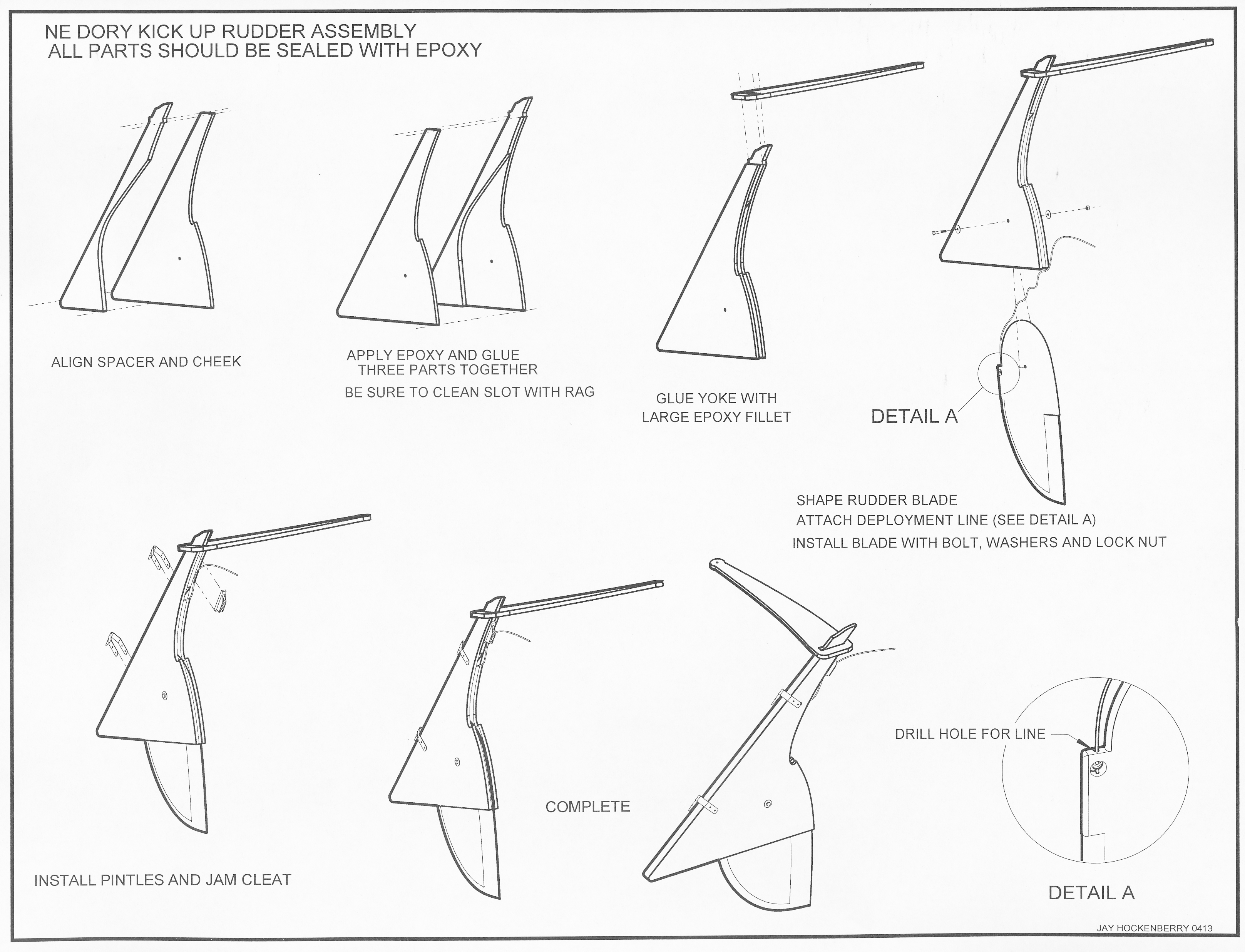

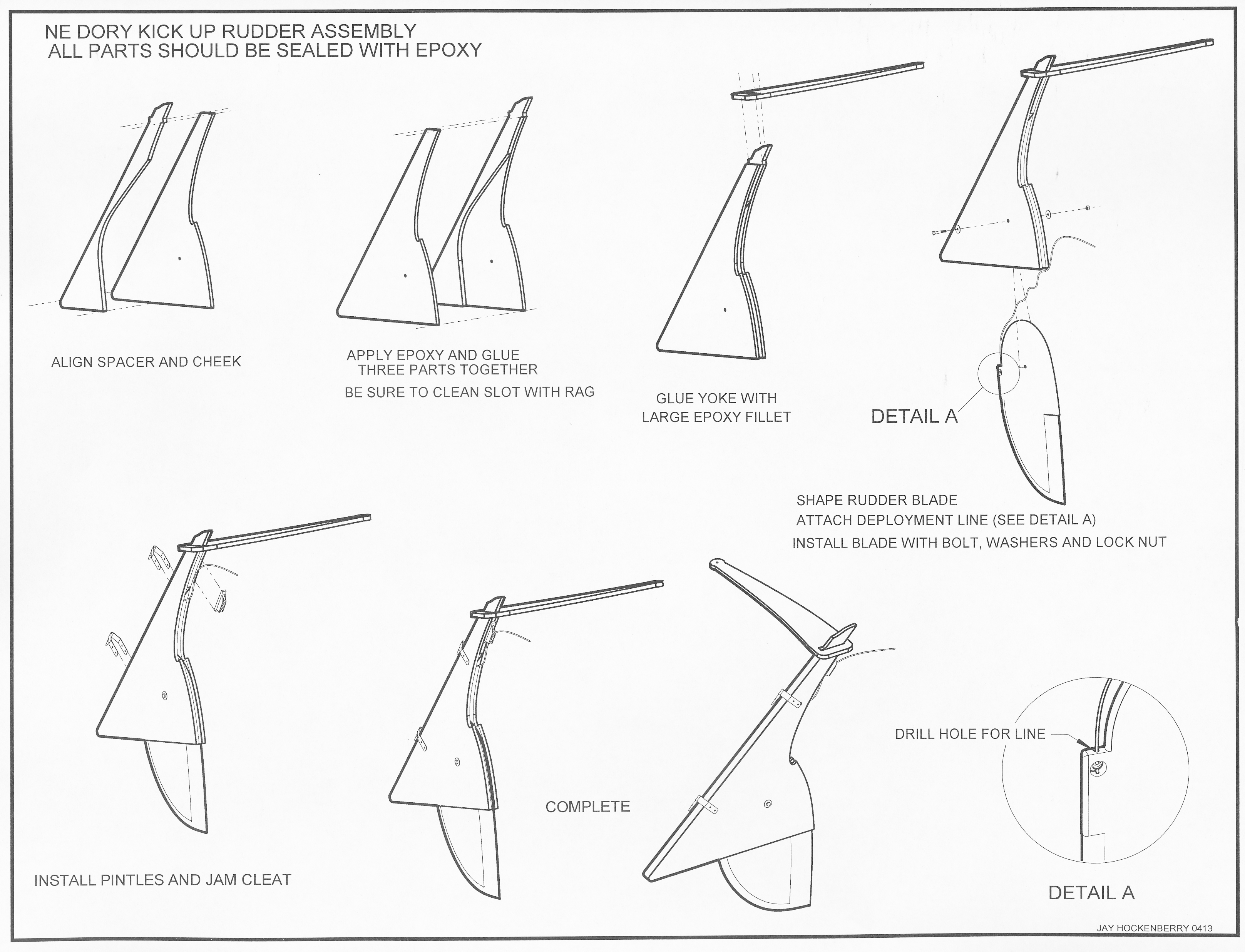

A few people have installed kick-up rudders on Northeaster Dories. The relatively deep, narrow blades on those are given as much shape as the daggerboard.

RE: NE Dory rudder vibration

Thanks for all the info! I will reshape the trailing edge.

Are there plans for the kick up rudder? It would be easier for beach launchings and landings than leaning over the transom.

RE: NE Dory rudder vibration

Thanks to all! John, I followed your suggestion and in a couple of hours of good sailing last week, there was no vibration.

Is there a way to modify the standard rudder to make it a kick up?

RE: NE Dory rudder vibration

>>>>>Is there a way to modify the standard rudder to make it a kick up?

It's an entirely different assembly. All that would transfer would be the pintles.

RE: NE Dory rudder vibration

» Submitted by Laszlo - Sun, 4/20/14 » 7:12 AM

Barry,

I don't have a Dory but I've had that problem. It means that something is operating stalled. It's either the rudder shedding vortices that cause turbulence or it's something upstream of the rudder shedding vortices that the rudder is riding through. Most likely it's the rudder stalling.

When I had that happen it was because the rudder was too flat. I was able to fix it by improving the the foil shape so that it went through the water without stalling. If it's not flat, make sure that it is smooth and symmetrical. No dips or bumps because they can make the flow separate and cause stalling.

If the rudder shape is a really good foil, then check the mechanical attachments. If they're loose or the axis formed by the upper and lower pintles is not straight and tight, the rudder could vibrate. This could cause a rapidly changing angle of attack which could have your rudder moving in and out of stall. In addition, the vibration could hit resonance with the rudder, amplyfying it at certain speeds.

So it's ultimately a stall that could be caused by many things. Does the dagger board vibrate, too?

Good luck,

Laszlo